Efficiency, speed, and precision are the new currency of digital dentistry. For a high-volume dental lab or a contemporary clinic that offers same-day restorations, getting the correct dental milling machines can be crucial. As CAD/CAM becomes more sophisticated and restorations are generated in new and different ways, it is important to understand the various options that are available. In this guide, we thoroughly explain different types of machines, telling you the top models of 2025 and more. So you can invest with confidence to fulfill your clinical or lab needs.

What is a Dental Milling Machine?

Dental milling machines are essential in modern dental laboratories for creating precise restorations such as crowns, bridges, and dentures. Utilizing computer-aided design (CAD) and computer-aided manufacturing (CAM) technology, these machines mill dental materials with high accuracy and efficiency.

When selecting a dental machine, factors like material type, precision level, and production volume are crucial. Options include dry milling machines, wet milling machines, and combination machines that handle both wet and dry processing. These machines can mill single unit blocks and are particularly effective for implant-supported restorations.

Advanced dental milling machines have significantly evolved, drastically reducing production time and errors while enabling fully automated processes. This evolution allows for same-day restorations in some clinics, a major advancement over the weeks-long wait for dental prosthetics that previously required temporary appliances.

Dental milling, the computer-assisted process of cutting and shaping restorations, offers unrivaled precision. These machines feature durable construction and robust spindles, enhancing performance in wet grinding and grinding machines, making them ideal for both tabletop mills and larger setups.

Types of Dental Milling Machines

Not all dental milling machines are created equal, which is why there are many types, each designed to work best in a particular production environment. The most common types are:

Not all dental milling machines are created equal, which is why there are many types, each designed to work best in a particular production environment. The most common types include:

Dry Milling Machines

Dry milling is a process that does not require liquid to cool the cutting tool and milling stock. This method is suitable for materials like zirconia, composite resins, and wax, which can withstand high temperatures. Dry milling machines use pressurized air and/or a vacuum to remove material from the milling disk or block. Advantages include reduced mess and easier cleanup, as well as the ability to mill materials sensitive to water. However, dry milling can generate more heat and dust, which may be a concern for certain applications.

Wet Milling Machines

Wet milling uses liquid to cool the cutting tool and milling stock, preventing overheating and damage to the material. This process is ideal for materials such as glass ceramics and metals, which require cooling. Wet milling machines utilize water or specialized milling fluids to remove material efficiently. Advantages include improved precision and surface finish, along with reduced heat generation and dust production. However, wet processing can be messier and more difficult to clean, and the use of liquid coolant may pose challenges for some materials.

Hybrid Milling Machines

These machines provide versatility by accommodating both dry and wet milling processes, allowing dental professionals to choose the best method for their specific needs.

Chairside Milling Machines

Designed for dental clinics, these machines offer optimized usability for in-office, same-day patient restorations, making them ideal for immediate treatments.

Lab Milling Machines

These larger, more robust machines are built for high-volume dental labs, allowing for efficient production of multiple restorations.

5 Best Dental Milling Machines for Sale in 2025

Digital dentistry is a quickly evolving industry; hence, finding a suitable dental milling machine is vital for precision, efficient operation, and quality restorations. Here are the five best dental milling machines of 2025, complete with a range of different individual features to suit different clinical and laboratory needs.

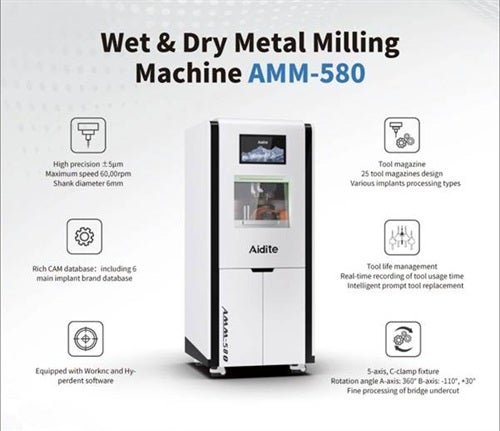

Aidite AMM-580

The Aidite AMM-580 is a highly versatile and precise 5-axis dental milling machines (dofollow). Suitable for dry and wet milling, outer materials also include zirconia, PMMA, and wax. The user interface and performance are good enough to be considered an asset for dental laboratories serving high-quality output.

Key Features:

- Simultaneous 5-axis milling for complex geometries

- Works with different materials: zirconia, PMMA, wax

- Easy to use interface with simple controls

- Consistent performance, with a high level of accuracy

Pros:

- Works with a large variety of materials

- Precisely enabled milling abilities

- Suitable for new and larger productions

Cons:

- It must be periodically maintained for optimal performance

- A higher initial investment may be required for small clinics.

Price: This model falls into the mid-to-high range

Roland DGSHAPE DWX-53DC

Designed for ultimate efficiency and automation! The Roland DGSHAPE DWX-53DC is the next generation of high-speed milling. Integrated with a 6-disc changer and intelligent tool mechanism, it reduces human interference & provides uninterrupted operation and works to boost productivity. Perfect for dental labs with a need for stable, high-volume production.

Key Features:

- Automatic 6-disc changer for continuous milling

- Smart tool control system

- Works on different types of materials

- Cleaner work area with improvements in dust collection

Pros:

- Extensive automation minimizes manual work

- Performance is predictable and reliable

- Compatible for Industrial usage

Cons:

- Higher initial cost

- Might have a learning curve to maximize its set of features

Price: This high-end machine is best suited for large labs

vhf Z4

The vhf Z4 is an in-office chairside milling machine for same-day restorations. It features wet milling capabilities, allowing for the processing of materials such as glass, ceramics, and composites. It is a relatively simple and quick process that yields results quickly, making it popular among dental clinics that prioritize patient convenience.

Key Features:

- Wet milling for high-quality surface finishes

- Small-footprint chairside design

- Fast milling times for same-day restorations

- User-friendly interface

Pros:

- Great for same-day, in-clinic procedures

- Effortless services producing quality results

- Low footprint—space efficient

Cons:

- Applicable only for materials to be wet milled

- Does not scale well for lab productions in bulk

Price: Positioned in the mid-range category

4. imes-icore CORiTEC one

The imes-icore CORiTEC one is a flexible milling machine that is designed to meet the demands between chairside and laboratory. It has wet and dry milling capabilities and can handle many different materials. Designed to serve flexibility and accuracy, it is a perfect choice for clinics and small labs, comprising advanced features in a compact form factor.

Key Features:

- 4-axis milling for diverse restorations

- Suitable for both dry and wet milling

- Space-saving design with a small parcel size

- An open source for easy integration

Pros:

- Flexible milling options

- Appropriate for various materials

- Seamless integration with the current workflow

Cons:

- Not Ideal for Mass Production

- First-time setup might need tech support

Price: With an entry to mid-level price tag

5. Planmeca PlanMill 50 S

The Planmeca PlanMill 50 S is a super-fast 5-axis milling unit. This unit is built for laboratories that need power without sacrificing flexibility and precision. Quiet in sound output, wide material compatibility, excellent for demanding lab environments.

Key Features:

- 5-axis milling with an ATC tool setting above the slide

- Low noise & vibrations

- Compatible with almost all materials of dental components

- Easy-to-use CAM interface

Pros:

- Exceptional surface finish characteristics

- Indicated for restorations that are complex and large

- Particularly low noise operation improves the working environment

Cons:

- Not appropriate for chairside environment

- Could be expensive for low end labs

Price: It falls into the upper mid-range

How to Choose the Right Milling Machine?

Here are a few considerations when choosing the best dental milling machine:

Material Compatibility

Ensure the machine can work with materials such as zirconia, PMMA, wax, and ceramics relevant to your lab's needs.

Production Volume

For high-output labs, look for machines with automatic tool changers and multi-disc support to enhance efficiency.

Axis Configuration

While simple restorations can be performed on 4-axis machines, 5-axis machines offer superior capabilities for complex designs.

Size and Footprint

Before purchasing, verify that there is enough space in your lab or clinic to accommodate the machine.

Software Integration

Select machines that utilize open-source CAM systems for greater flexibility in your workflow.

Support and Warranty

Choose brands that provide comprehensive technical training and reliable after-sales support to ensure long-term satisfaction.

Dental Milling Machine Price

Consider the feature set that fits your budget. Prices can range from $15,000 to over $100,000, depending on specifications. Also, assess the quality of the stock or milling spindle, as this can greatly impact performance and durability.

Conclusion

Dental milling machines are the key to digital dentistry because they provide solutions for clinics and laboratories to offer rapid, accurate, and high-quality restorations. Knowing what is dental milling and the comparison will enable you to choose a better investment. The best dental milling machine for your workflow, volume, and materials for professionals looking to upgrade.

For those looking to scale a dental lab or bring work inhouse with chairside digital milling, the Aidite AMM-580 is a reliable option for industry! To get a wider range of options and support, refer to Aidite Dental Equipment (nofollow).